Bandsaw Features: Key Considerations When Purchasing

The right bandsaw can help improve your woodworking skills. Below are 7 important features to consider when purchasing a new bandsaw. Also see beginner bandsaw projects.

Features to Look for When Choosing a Bandsaw

There is a wide range of bandsaws on the market. Below are seven key features to consider when looking for a versatile bandsaw. For more information see choosing the right bandsaw blade and bandsaw benefits.

1. Look for a Bandsaw That Uses Replaceable Plastic “Table Inserts”.

A “table insert” or “throat plate” helps reduce splintering, tear-out and to keep small pieces of wood from falling between the blade and the table. A plastic plate will not cause any damage to the blade if the teeth accidentally touches it. A good bandsaw will allow you to easily replace a damaged table insert.

2. Consider Bearings over Solid Guides.

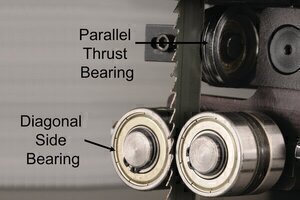

Bearings or solid guides help prevent the blade from being pushed back and minimize any side deflection in the blade. Less expensive models use solid guides. Whereas, more expensive models use bearings. In general bearings provide a more accurate cut and show less signs of wearing, even after years of use.

As shown in the image above, the “Parallel Thrust Bearing” prevents the blade from being pushed back. The “Diagonal Side Bearings” minimize any side deflection in the blade. When cutting is not taking place, there should be a small gap approximately 1/64” (0.4mm) between the blade and all the bearings. In this non-cutting state, the bearings should not be rotating. As cutting begins, the blade will move back and make contact with the thrust bearing causing it to spin. At the same time, one of the side bearings will also most likely make contact and start spinning. Only the flat part of the blade (not the teeth) should make contact with the guide assembly.

3. Look for a Bandsaw with a Tilt Table.

A tilting table allows you to create angled or beveled cuts.

In general, most people feel bevel cuts are more aesthetically pleasing.

4. Motor Power

Bandsaws come with all different size motors. On the small side are benchtop models with 1/3 HP (250 watt) motors. On the large side are stand-alone models with 5 HP (3730 watt) motors. Generally, a 1.5 Horsepower saw can handle 2″ materials easily. However, if you plan on ripping 10″ thick lumber, you will want to consider going with a 3HP or 5HP machine.

5. Cutting Capacity

On the small side are benchtop models with 3” (8cm) cutting capacity in height, 9” (23cm) cutting capacity in width. On the large side are stand-alone models with 15” (38cm) cutting capacity in height and 24” (61cm) cutting capacity in width.

6. Size and Construction

If you have a large workshop, then definitely consider a standalone machine. However, if space is tight, then a benchtop model might be your best choice.

Standalone Bandsaw – a standalone band saw has a floor-standing configuration. It has a frame that allows the saw to stand upright. The advantage of this design is that it enables a user to cut larger pieces and move freely. A standalone configuration takes a considerable amount of space in the shop, but allow you cut much larger pieces.

Benchtop bandsaw – a benchtop bandsaw can be mounted on an existing workbench – saving you space. Some benchtop models have a compact design and are best suited for delicate and precise projects.

7. Keep in mind a bandsaw can only create “external” cuts.

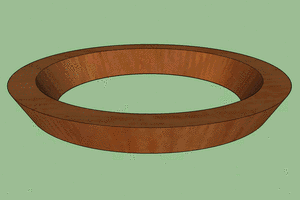

While a band saw can cut curves and irregular shapes, it cannot make “internal” cuts such as removing the inside of the ring shown shown below. See jigsaws and scroll saws if you are looking to create internal cuts.

Conclusion

Woodworkers typically use the bandsaw to cut curved or irregular shapes or to re-saw thicker boards into thinner ones. With many uses, many people consider the bandsaw as one of the most useful tools in the shop. Whether ripping wood, creating round blanks, or removing corners on square stock, the bandsaw can make the initial steps of turning much easier and safer. Hopefully, you can now be determine what would be the best bandsaw for your shop. Some common bandsaws brands include: Jet, Grizzly, Delta, Rikon, DeWalt, Laguna, Makita, and Powermatic.

As shown below, the band saw makes it very easy to create bowl blanks.

More Bandsaw Projects and Tips

Pin for later!

Looking for more WoodWorking Tips and Tricks?

Looking for more WoodWorking Projects and Plans?

You will also find patterns of all 50 US States.